Ukushaya Nokufa Kokucindezela Ithebhulethi

Izici

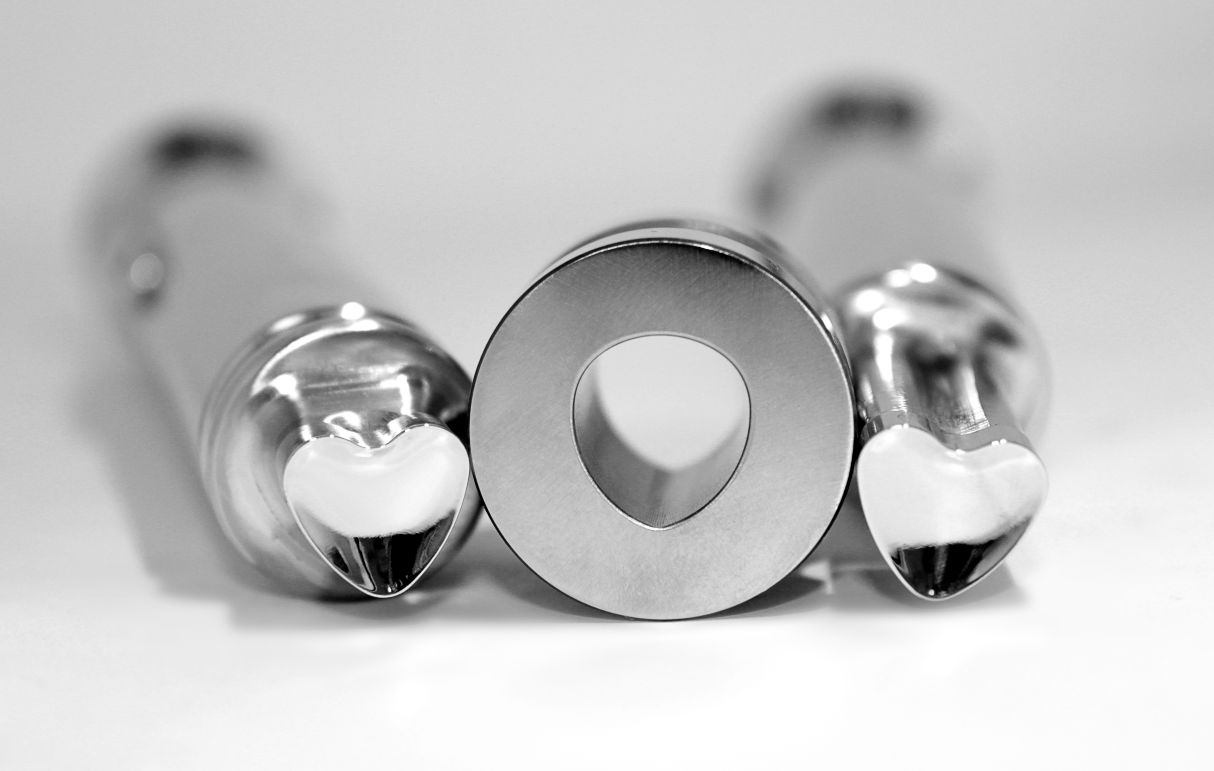

Njengengxenye ebalulekile yomshini wokucindezela amathebhulethi, i-tableting Tooling yenziwa ngokwethu futhi ikhwalithi ilawulwa ngokuqinile. E-CNC CENTER, ithimba lokukhiqiza lochwepheshe liklama futhi likhiqize ngokucophelela i-tableting Tooling ngayinye.

Sinolwazi olucebile lokwenza zonke izinhlobo zezibhakela kanye nama-dies afana nesimo esiyindilinga nesikhethekile, i-concave engajulile, i-concave ejulile, i-bevel edges, i-de-tachable, i-single tip, i-multi tip kanye ne-hard chrome plating.

Asigcini nje ngokwamukela ama-oda, kodwa futhi sinikeza izixazululo eziphelele zamalungiselelo aqinile ukusiza amakhasimende ukuthi enze izinqumo ezifanele.

Ngokusebenzisa ukuhlaziywa okuningiliziwe kwe-oda langaphambilini yithimba lenkonzo yamakhasimende elinolwazi ukuze kugwenywe izinkinga. Ngokulawulwa kwenqubo yokukhiqiza okuqinile kanye nombiko wokuhlola oqediwe ukuqinisekisa ukuthi wonke ama-Tooling angamelana novivinyo.

Ngokwezidingo zamakhasimende, asigcini nje ngokuhlinzeka ngama-punch nama-dies ajwayelekile, njenge-EU ne-TSM, kodwa futhi sihlinzeka ngethuluzi elikhethekile lokufaka amathebulethi ukuze sigcwalise izidingo zamakhasimende. Izinto zokusetshenziswa ezahlukene zama-punch nama-dies kanye nokugqoka, okungaqedwa kuphela ngeminyaka yesipiliyoni.

Ama-tableting asezingeni eliphezulu Ama-tableting avumela umshini wokucindezela ithebhulethi ukuthi wenze izinhlobo ezahlukene zama-tablet. Ama-tooling ahlukahlukene amaningi akhulisa umkhiqizo futhi anciphise isikhathi sokukhiqiza.

Ukulungiswa

1. Ngemva kokuphela kokukhiqiza, ukuhlolwa okuphelele kwe-Tooling kuyadingeka;

2. Hlanza futhi usule isikhunta ngokuphelele ukuqinisekisa ukuhlanzeka kwe-Tooling;

3. Hlanza imfucuza ku-Tooling ukuqinisekisa ukuthi akukho mafutha angcolile ebhokisini lemfucuza;

4. Uma igcinwe okwesikhashana, yifafaze ngowoyela wokulwa nokugqwala ngemva kokuyihlanza bese uyibeka ekhabetheni le-Tooling;

5. Uma i-Tooling izobekwa isikhathi eside, yihlanze bese uyibeka ebhokisini lesikhunta elinedizili phansi.

Izigaba zemikhiqizo

Iphephandaba Lethu Lamasonto Onke

Kuyiqiniso elidala ukuthi umuntu ozolungisa izinto uzoneliseka yi-

okufundekayo kwekhasi uma ulibheka.

-

I-imeyili

-

Ucingo

-

I-Whatsapp

-

Phezulu