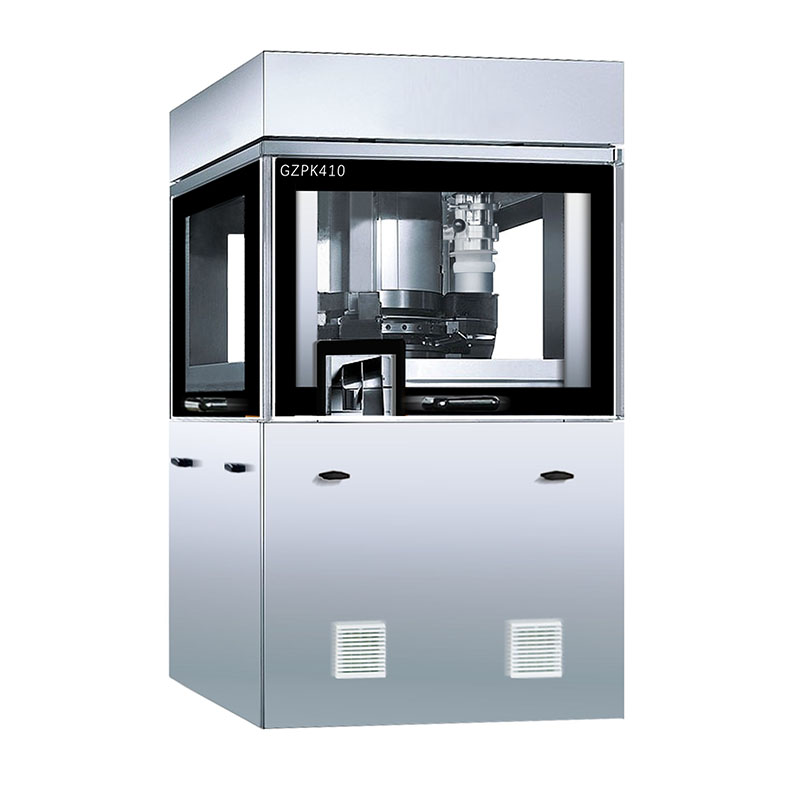

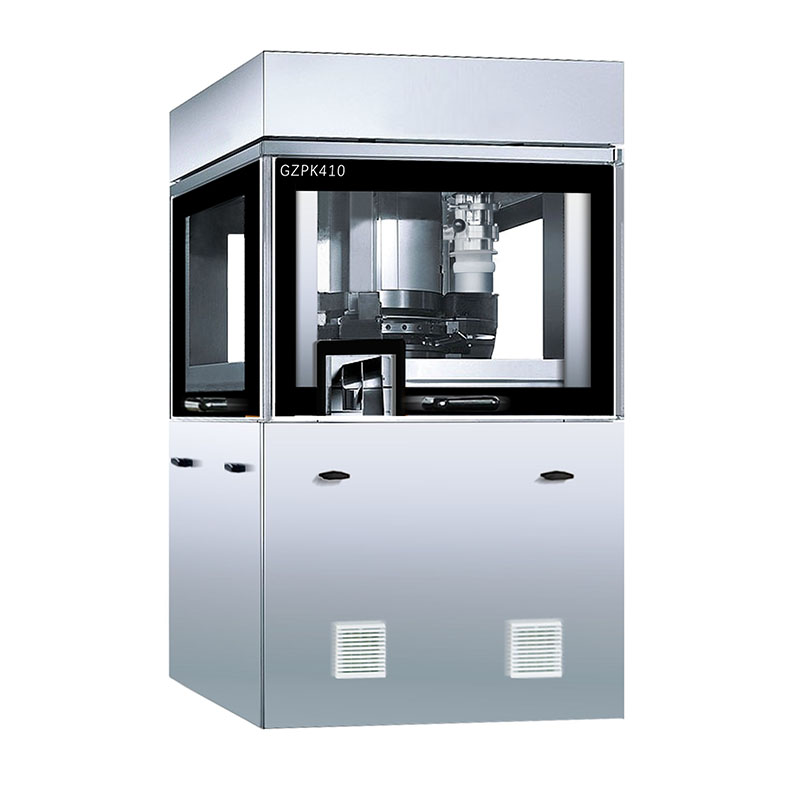

Umshini omusha othomathikhi we-automatic single auple shEPETER Speeter Compression Machine

Incazelo echazayo

I-GZPK410 Uchungechunge oluzenzakalelayo lwe-Tablet lwe-Tablet lwe-Tablet lune-design ehlukile yokucindezela kanye nokulawula kanye nendlela yokutholwa. Ukusebenza okulula kungathatha indawo ngokushesha ipuleti lokubhoboza, ukuze amadayimane ahlukene wethebhulethi nezinhlobo zethebhulethi zingatholwa emshinini ofanayo ngaphandle kwezinguquko. Kungumshini ophakeme ophumelelayo ofinyeze nesikhathi sokuhlanza nokusonga isikhathi.

Hlisisa

1.Witho i-turret.

I-2.Duble Sihlalo ngejubane elikhulu lethebhulethi yethebhulethi yokukhiqizwa kwesisindo.

Ukusebenza kwe-3.Excellent kwezinto ezinzima.

Indlela yokuqoqa ye-4.Dust enesakhiwo esingu-5.

5.Kungenza ungqimba olulodwa nethebulethi ephindwe kabili.

6.Wuth Ithebhulethi ye-Tablet Sampling yethebhulethi yesendlalelo 1

I-7automatic wenqatshwa systemford ithebhulethi engafaneleki.

80Ukulungiswa kobulukhuni obuqinile, ukugcwalisa ukujula kanye nokucindezelwa kwangaphambili.

I-9.Automatic Wenqabile Uhlelo lwethebhulethi engafaneleki.

Ama-10.Coluns yizinto eziqinile ezenziwe ngensimbi.

11.UMachine uphethe iKhabhinethi elizimele kagesi ne-Operation IKhabhinethi ngokufanelekile ukungcoliswa kwempunye.

I-12Lay Force iqukethe ama-paddle amathathu angenamkhawulo angenamkhawulo ngokudla okuphakathi okuqinisekisa ukuhamba kwempuphu futhi kuqinisekise ukunemba kokudla.

I-13.Kuhlulwe nge-Eject Force Salt for the punches ephansi.

14.Recipes Isitoreji Umsebenzi wokwahlukahlukana kwemikhiqizo engaphansi kokulungiswa.

I-15.With uhlelo oluzenzakalelayo oluzenzakalelayo, kufaka phakathi ikhanda eliphakeme lomphindisi kanye nokuthambisa kwangaphakathi.

Imininingwane ye-16.Production ingagcinwa e-USB ngezithombe.

Ukuqapha okungu-17.Kuqashwa kwawo wonke amaPresspasepameter aphambili nakwesiko lama-roller, force ejection, kanye nokuqapha kanye nomdwebo wengcindezelo eyodwa yamaphayini.

Iphrinta ye-18

I-19.UMachine iza nemibhalo ephelele ye-IQ OQ PQ Sat Sat Fat Andce.

Umsebenzi wezilungiselelo ze-Femote (ngokuzithandela).

Umsebenzi wesiginesha we-19.Electronic ohambisana no-21 CFR ingxenye 11 (ngokuzithandela).

Izici

Umsindo we-1.low <70 db.

2.With umsebenzi ophephile umnyango.

Ingcindezi ye-3.Main, ingcindezi yangaphambi kwengcindezi kanye ne-feedingsystem yonke yamukele imoderar.

I-4.predure ilinganiswe ngokuqondile nge-transducer ye-Force.

5.I-Express Pressure Pressure Easy Kulula ukuyihlanza futhi kulula ukuyicasuka.

6.With ukukhishwa okuvaliwe kumtshina wensimbi kanye ne-de-duster.

7.Izingxenye zokubopha zingashintshwa ngokukhululekile noma zisuswe okulula ukulungiswa.

I-admain ingcindezi roller kanye ne-roller yangaphambi kwengcindezi kungubukhulu obufanayo obungasetshenziswa ngokushintshana.

I-9.both Main Pressure Wheel kanye nesondo lokucindezela kwengcindezelo kulungiswa ngama-motor avumelanayo ngokunemba okuphezulu okusheshayo.

10.I-Middle Turret Material yi-2CR13, ubulukhuni bendawo bungafinyelela ngenhla kwe-HRC55. Inobunzima obuhle, gqoka ukumelana nokuphikiswa kokugqwala.

11.Izitimela zokugcwalisa ezigcwaliswayo zijika zamukela amajika we-cosline, futhi amaphuzu wokugcoba afakiwe ukuze aqinisekise ukuqinisekisa impilo yenkonzo yamajantshi wokuqondisa. Iphinde inciphise ukugqokwa kwama-punches nomsindo.

12.Imigwaqo ye-cams kanye nojantshi wemizila iyacutshungulwa yi-CNC.

13.Kungani umfutho kanye nokuphambuka kweqembu ngalinye lama-punches, inani lamaphilisi asezingeni eliphakeme, amaphilisi angalinganiswanga nesikhathi sokusebenza, nesikhathi esiphelele somshini.

Imisebenzi engu-14.Protection njengaphansi:

●Ukuvikelwa komshini kanye nokudla okugcwele ngokweqile;

●Ingcindezi enkulu nokuvikelwa kokugcwala ngokweqile;

●Ukuvikelwa okuqinile okuqinile kwesifo sohlangothi esiphezulu kanye nohlangothi oluya phansi '

●Ukuvikelwa kwesikhundla sokufaka sedivayisi yokulungiswa kwesisindo sethebhulethi;

●Ukuvikelwa kwebhlokhi;

●Ukuvikelwa kwezinga lamafutha;

●Umnyango nokuvulwa kwewindi lokuvula;

●Ukuvikelwa okukodwa okuqhubekayo kokuvikelwa kokungabekezeleli;

●Ukuvikelwa okuqhubekayo okuqhubekayo kwesisindo sethebhulethi;

●Izikhathi zokulungiswa kwezikhathi ngaphandle kokubekezelela.

Ukucacisa okukhulu

| Isifanekiso | Gzpk410 | |||

| No.of Tunch Iziteshi | 30 | 36 | 43 | 47 |

| Uhlobo lwe-punch | D I-EU1 '' / TSM1 '' | B EU19 / TSM19 | BB EU19 / TSM19 | Ama EU19 / TSM19 |

| Ukucindezelwa Okusemqoka (kn) | 100 | |||

| Ukucindezelwa kwangaphambili (kn) | 100 | |||

| Ijubane le-Max.turret (RPM) | 100 | I-120 | I-120 | I-120 |

| UMax. Okukhipha (ama-PC / H) | I-180000 | 250000 | 300000 | 330000 |

| UMax. Ububanzi bethebhulethi (mm) | 25 | 16 | 13 | 11 |

| Ukujula kwe-max.fing (mm) | 18 | |||

| Amandla aphelele (kW) | 13 | |||

| I-Pitch Circle Raideter (MM) | 410 | |||

| Isisindo (kg) | 4000 | |||

| Ubukhulu bomshini wokucindezela wethebhulethi (MM) | I-1200 * 1450 * 2010 | |||

| Ubukhulu beKhabhinethi (MM) | 890 * 500 * 1200 | |||

| Ubukhulu beKhabhinethi Kagesi (MM) | I-1000 * 800 * 1100 | |||

| Ukunikezwa kwamandla kagesi | 380v / 3p 50hz* Kungenziwa ngokwezifiso | |||

Imikhakha Imikhakha

Iphepha lezindaba zethu masonto onke

Iqiniso elide elisungulwe ukuthi i-redler izogoqa ngu

Ukufundwa kwekhasi lapho ubukeka.

-

I-mail

-

Ifoni

-

WhatsApp

-

Isihloko